Without Wind

Without wind describes the problem to be overcome very well.

Even in the days of the P-liners, when steam engines were industrialising the world, sailors thought that steam-powered windmills should be erected ashore to provide wind for sailing ships in doldrums!

Some traditional ships I have sailed had motorisation called auxiliary engines. The pilot schooner No. 5 Elbe has an engine with a few horsepower, whose propeller protrudes sideways from the hull and is neither suitable for sailing astern nor for harbour manoeuvres. The tjalk “Zwarte Ruiter”, which I skippered in the Netherlands, was the last cargo ship under sail in 1968. Under sail, it towed a dinghy called an opdiuwer with a glow-head single-cylinder diesel engine, which slowly pushed the tjalk forward in calm conditions and helped it moor in the narrowing harbours. Large dents on the stern still bear witness to this practice today. In the form motorised as a yacht, we drove a Perkins 4 cylinder with 68 hp on the tjalk. At 100t, this resulted in a ratio of 0.68. Today, yachts of 10t run with 80hp and arrive at a ratio of 8hp per tonne.

With catamarans, the engine weight is the main problem.

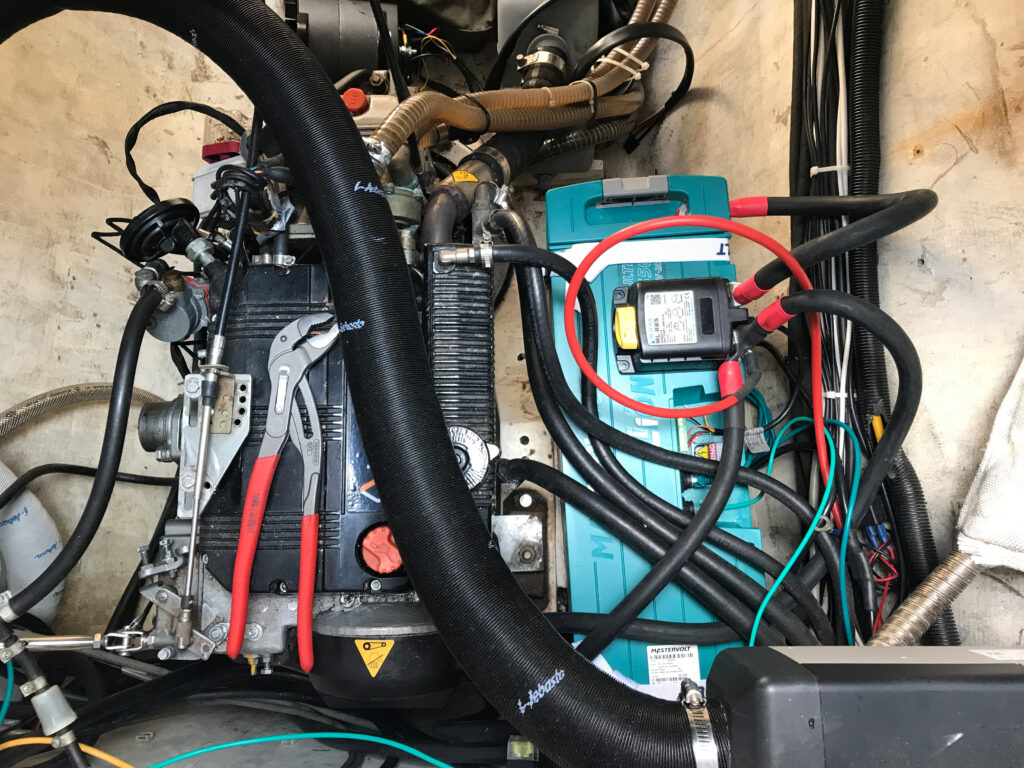

Our boat has two Lombardini LDW 1003 with Saildrive of 141kg, which produce 29hp and 22hp. These inexpensive engines have one of the best weight/power ratios and in our case are equipped with Gori folding propellers, which offer the Over Drive mode as an additional drive option to reduce the speed. The engines are still performing well after 1500h; the electrics, on the other hand, needed a refit.

Electrical refit 2020

Against the advice of various “experts”, we multiplied the alternator output: from 12V/35 A to 24V/ 150A. To do this, we had to construct our own alternator foundation and flange it to the machine foundation. The existing double belt pulleys could be used and drive the Mastervolt alternator with a pully factor of 1.36. The LiMa comes in at 22.5 A. The alternator is then driven by the Mastervolt. At 2200 rpm the LiMa has a power of 24V/150A. When both engines are running, the 11kWh of the Mastervolt lithium-ion batteries are fully charged with 300 A in 90 minutes.

This charging power is roughly equivalent to a 7 KW generator, which we have saved ourselves by this conversion.

The engine malfunctions feared by the experts, such as:

- Stalling at idle

- Overheating

- Rapid wear of the V-belts

- Engine vibrations

have not occurred even after 300 hours in 15 months. On the contrary: with the larger flywheel mass due to the huge alternators, engine running has become much smoother. The engine speed is lowered by 800 rpm when the limas are switched on; arithmetically, they take about 8-10 hp of power away from the engines. This is of no consequence when sailing at sea, but we can switch off the LiMas electrically at the helm so that this power is still available when manoeuvring in the harbour.

Light wind sailing under engine:

Over time we have developed a very efficient technique for sailing in light (2-5 knots) winds. We sail code 0 and mainsail hauled close and let the opposite engine run in over drive and charging mode. At about 1800 rpm we then have a boat speed of 6-7 knots. There is no way we would achieve that with just the engine or just the sail. The combination of engine and wind doubles our speed and range at the same time.

To maintain our minimum target of 5 kn per hour without any wind at all, one engine is completely sufficient. The drift of 2° that has to be corrected is of little importance, as we take the daggerboards completely out of the water under engine power and thus reduce the water resistance.

Daggerboards:

The daggerboards are a great advantage when sailing. We sail at about

- 60% without daggerboards on a course of 100° – 160°

- 30% with half daggerboards at half wind 70° – 100°

- 10% with full centreboards high on the wind 40° – 70°

We only sail with wind from astern if we are limited in our choice of course and the tide is running against us.

Using both engines

We use both engines to sail against the tide and wind when tacking is not worthwhile or when the course is constantly changing, such as in rivers or on tidal flats. And of course during harbour manoeuvres.

Our two steering positions are very helpful here. They make it possible to see the mooring manoeuvre exactly on both sides. Under engine power in the harbour, the rudders are rarely used, as they have no rudder effect at slow speeds. When manoeuvring and mooring with catamarans, I have got into the habit of giving direction with only one engine; the other engine supports the direction. In tight turns, it’s better to give careful astern with the inside engine than to go with more throttle with the outside engine. With practice, you can even put a cat in sideways against the wind with alternating, back-and-forth, give-and-take. Keeping into the wind works best backwards. In harbour manoeuvres we run our daggerboards to full depth of 190cm, water depth permitting.

Reaction in case of engine failure:

It is very exciting when one of the two engines fails unexpectedly. You have to practise this beforehand.

With the helm in the spoke grip, the rudder position is set to full deflection extremely quickly and the still running engine is only driven very carefully.

In a Dutch lock, where the machine didn’t start anymore, countersteering with the rudder wasn’t enough. There I had to give full throttle with the opposite rudder fully applied and then alternate slowly backwards to compensate, and then give full forward again. In the process, the boat slowly built up the speed necessary for rudder action while making S-curves.

We used a different method on our 2000 nautical mile trip to Portugal. On this trip, the freshly serviced starboard engine failed for some unknown reason while still in the English Channel and seemed beyond repair. We then had to decide to break off the journey in Brest or to continue with only one engine. Which we did, because other ships also cross the Bay of Biscay with only one engine 😉

Cool harbour tricks with dinghy:

For harbour manoeuvres, we then rigged the 8 hp dinghy to the starboard stern under the hull when entering the harbour so that it could help turn the ship in the harbour. To do this, the dinghy must be lowered into the water in good time with the engine, tied to the hull of the defective engine. The dinghy is steered by a trained crew member and eye contact must be maintained at all times, as acoustic communication is not possible in the wind and with the noise of the engine.

With the agreed commands in sign language, the harbour manoeuvres worked wonderfully: full ahead, full astern, engine to starboard or port. We docked and undocked so elegantly and didn’t put a single scratch on the ship.

For the numerous observers in the harbour, the manoeuvre was almost magical: when we docked, people thought my daughter was moving the whole ship with the tiny dinghy, because with the noise of the outboard motor, of course no one noticed that I was still moving the main load with the port engine.