Every two years the ship is put on dry land for maintenance of the underwater hull – sometimes it will be more…

Chaos in the crane

April 2021: Our crane appointment at 3 p.m. gives us a headache, because in the afternoon it is blowing hard in the Barlavento and then the water is low, which means little room for error.

High-spirited, we drive to the crane, which drives its crane gear into the water and waves us in. What we don’t know is that the yard manager is late and the belts are not deep enough in the water. As we drive in, we get tangled up and the crane workers start shouting – we have to get out backwards and they throw the lines loose again! We drift sideways under the concrete bridge and tear off almost all the railing supports on the starboard side! At the second attempt it works and we are driven to the yard. The shipyard manager and the crane driver got into a Portuguese argument about the cause of the damage.

We know this well from our experience as consultants: bad moods at work lead to mistakes and damage…

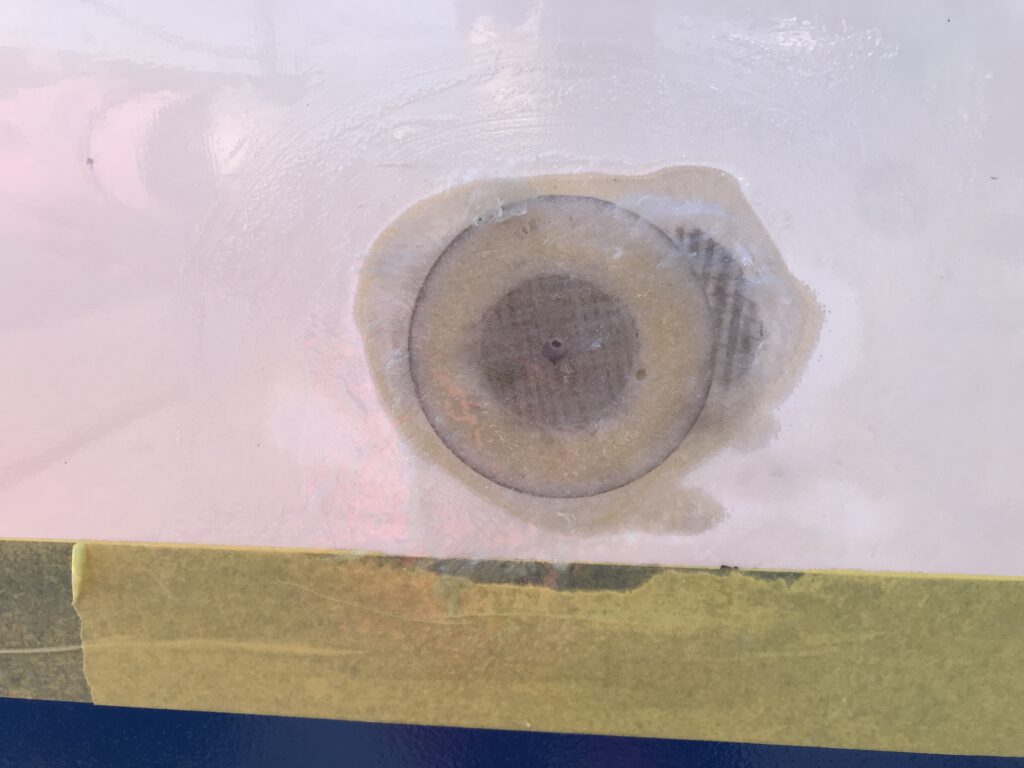

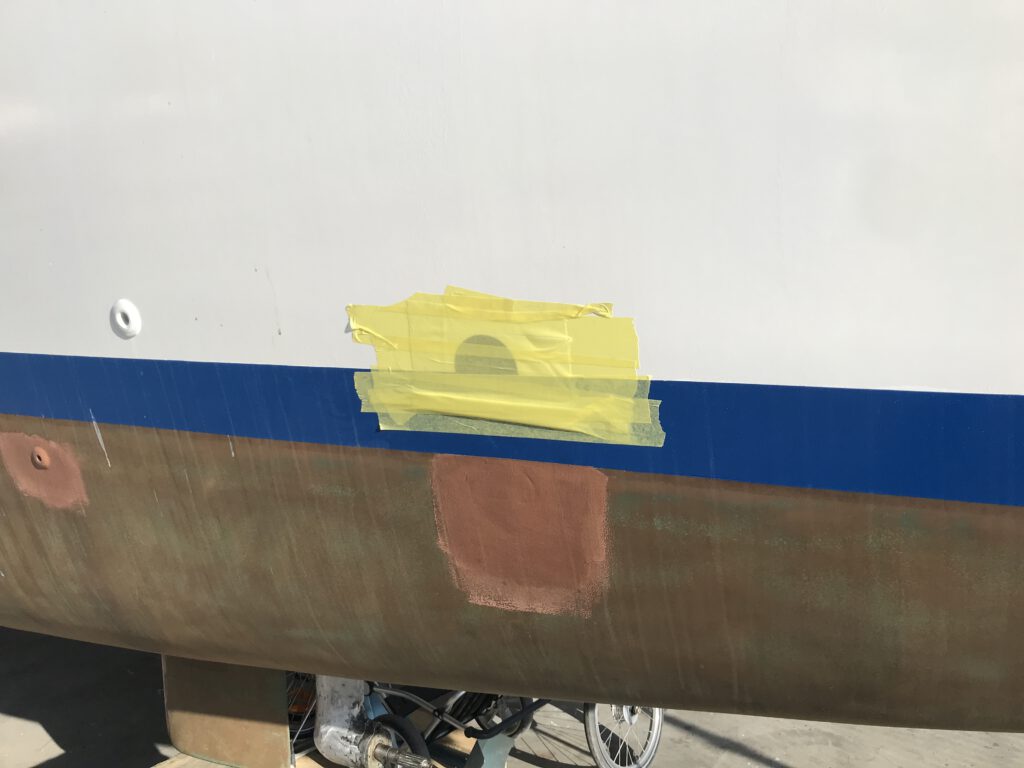

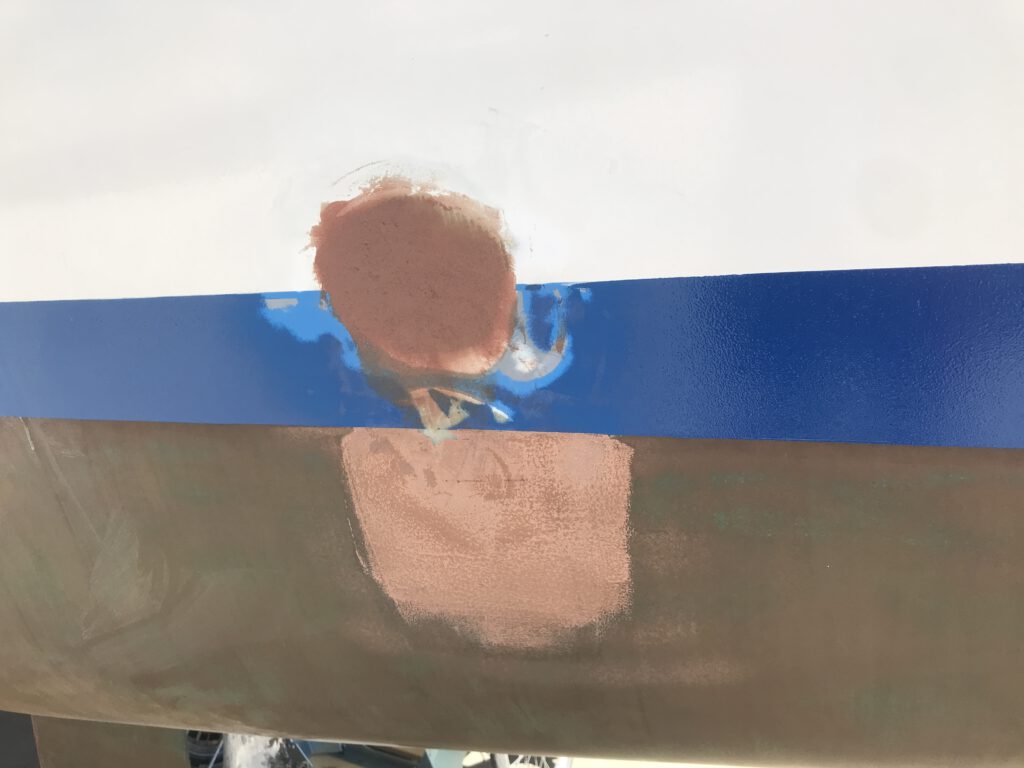

So the ship is hectically and carelessly jacked up in the rain, damaging the hull on the starboard side under the toilet: We have a hole in the ship!

Surveyors assess the damage, we come to an amicable agreement with the shipyard – but we can’t find anyone competent to repair the damage. We discuss the situation and then decide to laminate it ourselves with glass fibre and West epoxy system with vacuum.

Planned repairs and maintenance work

The following maintenance and repair work was on our list:

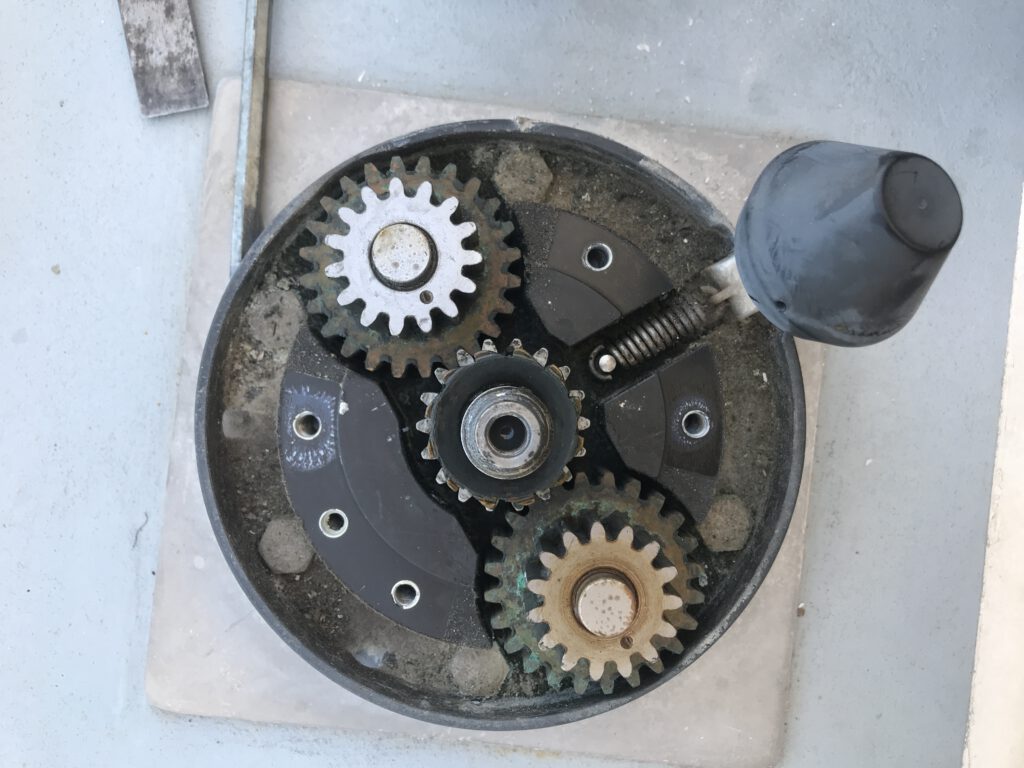

- Maintenance and service of the Gori propellers

- Grinding of the coppercoat to refresh and repair damaged areas

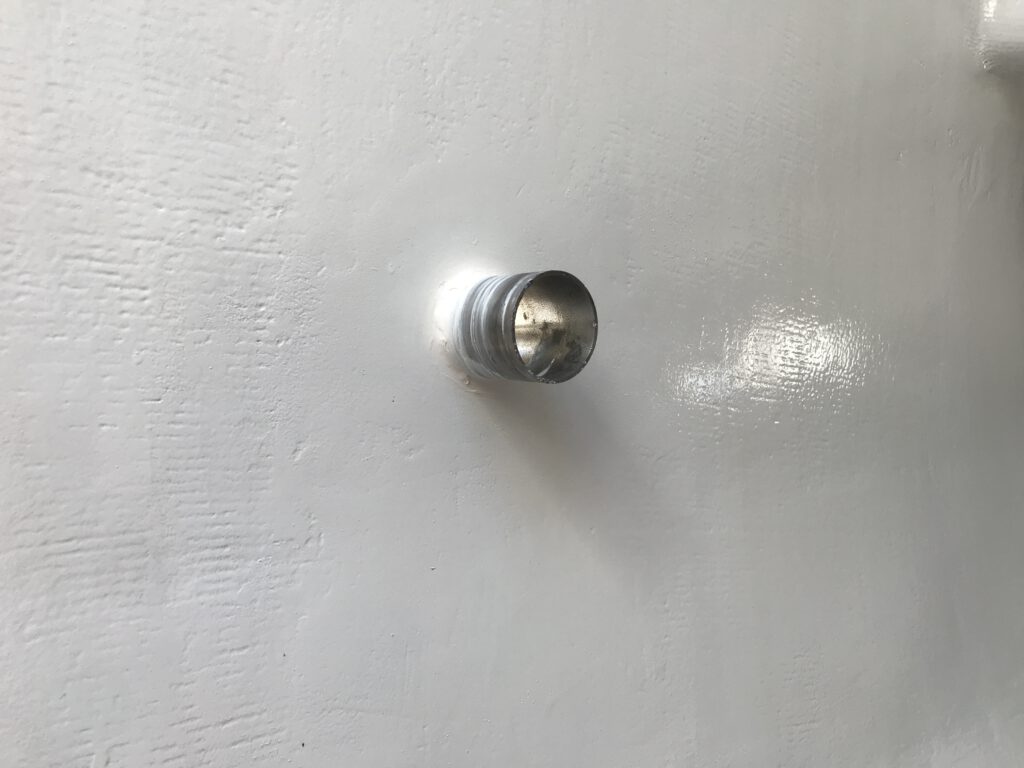

- Relocating a critical seacock (seawater inlet) from the bottom to the protected inside

- Installing a second shore connection and isolating transformers to prevent corrosion on the saildrive

- Maintenance of the Setamar winches stern incl. polishing of the base plates

- Reinforcing the rudder attachment with doubled stainless steel fittings and fibreglass epoxy

- Repair of the delaminated jib top with stainless steel cap

- Refreshing the markings on the anchor chain

- Installation of a holder for the reserve anchor

- Widening of the stern solar bracket to accommodate two additional Pheasun solar panels, adjusting the short-wave antenna bracket, polishing the stainless steel

- Repairing leaks in the window seals

- Installing higher Teflon fittings for the gangway

This additional work appeared unexpectedly and extended the shipyard time from the original 3 weeks to 3 months:

- New Variprop SPW propellers

- Repair of crane damage (torn railing supports, scratches on starboard hull)

- Repair of the shipyard damage: Sand the leak in the middle of the starboard hull extensively, vacuum laminate with epoxy fibreglass system, fine sand and coat with Coppercoat 3-4x

- Renew the hydraulics of the autopilot system

- Raise/Relocate the exhaust ports at the stern

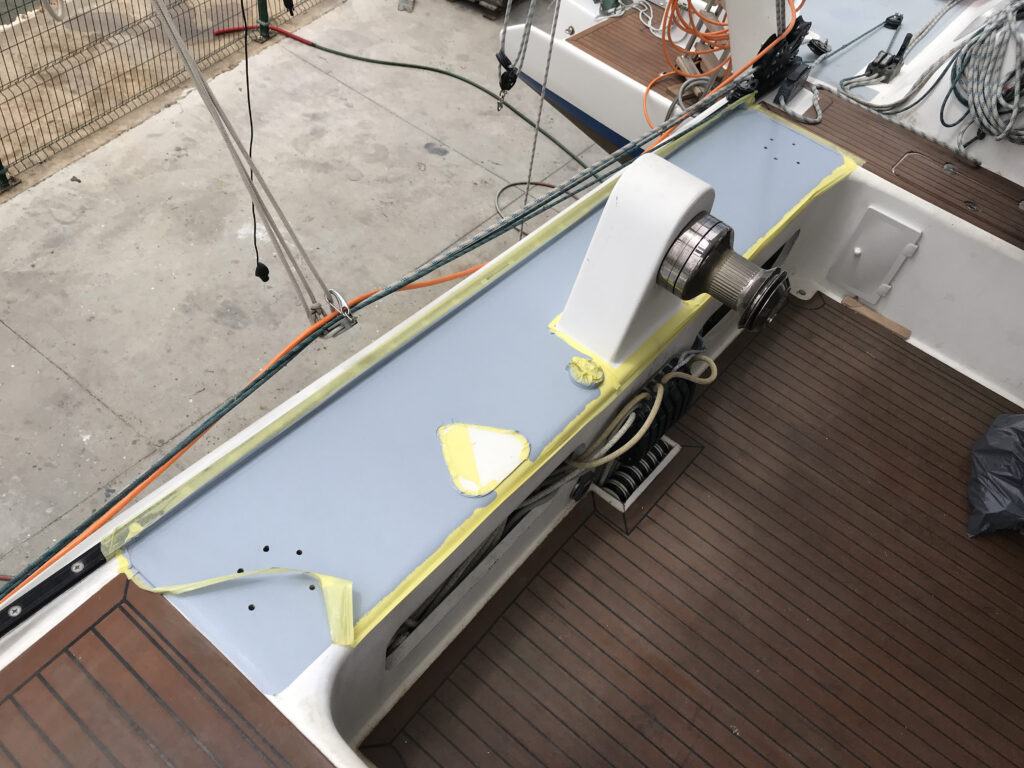

- Epoxy fibreglass repair on the beam with sanding and painting with 2 component system and antislip

- Painting the rudder bilges and the toilet bilges 2-component varnish

- Painting of the bathroom floor with 2-component varnish

- Partial renewal of the anti-slip coating

- Painting the outboard motor holder with 2-component varnish

- Rust removal and polishing of the stainless steel welding seams at the solar bracket at the stern

- Replacement of the drinking water pump due to defect